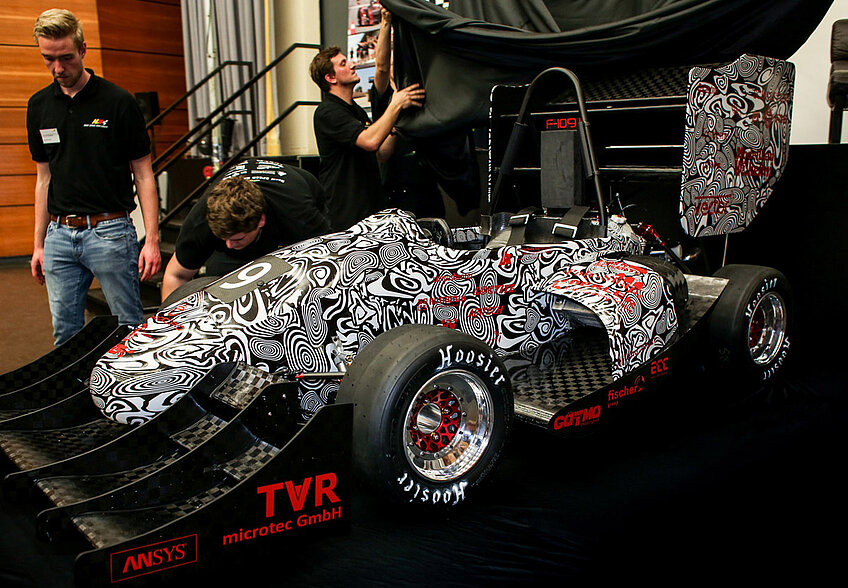

Putting on the finishing touches just before the first presentation: the racing car "F-109" built by students of Karlsruhe University of Applied Sciences (Photo: Campushunter/Pierre Buck)

Planned participation in student design competitions on Hockenheimring as well as in Austria and Spain

Again this year 59 students of Karlsruhe University of Applied Sciences jointly work on the construction of a formula racing car and the subsequent production. Students of Automotive Engineering, Mechanical Engineering, Mechatronics and Electrical Engineering, as well as Industrial Engineering and International Management, pursue a great common goal: the construction of their own racing car for the participation in this year's student design competitions of "Formula Student". They want to resume last year's successful participation, where they achieved excellent positions in the top third of the overall finish in Germany, Spain and Austria.

After nine months of development, construction and production they are having the rollout on 13 May 2015 and therewith achieve the first great milestone as they present the result of their project work – the racing car "F-109" – to the public for the first time.

The main task of the international design competitions of Formula Student is to develop a racing car that would be suitable for small series production. Therefore speed is only one aspect, the overall concept is assessed including acceleration power, brake performance as well as design, weight and calculated production costs. In order to develop a fast, maneuverable, safe, reliable and economic racing car, the students need to work due to a detailed project plan and coordination along with marketing strategy, business plan and cost report. Thus many engineering-specific abilities are demanded as well as extensive knowledge and competencies in the fields of economy and marketing. The concept behind this competition is to offer students an attractive possibility to put their engineering skills and expertise they are learning at university into practice.

For the new season the student team comes up with several technical refinements and mainly goes for a reduction of weight by a consequent use of lightweight construction. In addition the regulations regarding aerodynamics had been changed for the 2015 competitions. Here, the available area had been reduced so students are to use it in a most optimal way for aerodynamic effectiveness. For further weight reduction for the first time they are not using the hybrid construction method. Instead they manufacture the car body, which originally was composed of frame and carbon fiber reinforced (CFK) monocoque-lining, as a full-monocoque. Switching from a 13 to a 10-inch chassis results in further weight reduction. Great changes compared to the previous model can also be noticed when it comes to the motorization. By switching from a 600 cc four-cylinder to a 450 cc one-cylinder engine with about 60 hp they hope to achieve another weight reduction next to an improvement of driving dynamics and a minimization of fuel consumption.

"However, prior to producing the first component it was necessary to design all components in a CAD (Computer Aided Design) system ", says Nicole Müller, project leader of the student team, who is in her second semester of the International Management Master’s program. "Subsequently all critical components run through a computer simulation and single components were tested for instance in fracture tests. Only after bearing with the calculated loads, we could start the production. With the Institute of Materials and Processes at the university we had the unique opportunity to produce nearly all components by ourselves."

After the rollout of the "F-109" a short testing phase begins for the students in order to "limber up" their racing car for the competitions of Formula Student. The design competition "Formula Student Germany" at Hockenheimring, organized by the Association of German Engineers (VDI), takes place in August. This is followed by competitions at the Red Bull Ring in Spielberg, Austria and at the Barcelona-Catalunya Circuit in Spain.

"Despite the stress especially just before the rollout we are all highly motivated and proud of the result", Nicole Müller recaps the team's voice. "This project gives us students from different faculties the opportunity to put our knowledge and own ideas into practice while working in interdisciplinary teams."

"The combination of high quality and strong practical relevance is a central element of our university's educational concept and the further developed racing car of our students is again an impressive proof of this", comments the President, Prof. Dr. Karl-Heinz Meisel.

Back2024 © HAWtech KontaktImpressumDatenschutzbestimmungenLogin